The fins on finned tube coils increase heat transfer by augmenting the surface area available for heat exchange, leading to improved thermal performance in various industrial applications.

Finned tube coils play a crucial role in enhancing heat transfer rates due to their unique design and the properties of the materials used in their construction.

1. Fins on Finned Tube Coils: The Fins On Finned Tube Coils Increase Heat Transfer By

Fins on finned tube coils are thin, extended surfaces that are attached to the outer surface of the tube. Their primary purpose is to increase the heat transfer rate between the tube and the surrounding fluid.

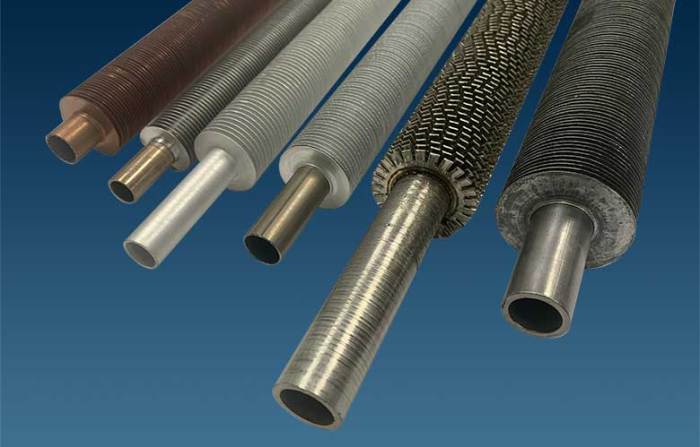

Types of Fins

- Plain fins:Simple, flat fins that are attached perpendicular to the tube surface.

- Serrated fins:Fins with a serrated or wavy surface, which increases the contact area between the fin and the fluid.

- Louvered fins:Fins with a series of parallel slits or louvers, which creates a more turbulent flow around the fin.

Industries Where Finned Tube Coils are Commonly Used

- HVAC systems

- Refrigeration systems

- Boilers

- Condenser and evaporator units

2. Heat Transfer Enhancement

Fins enhance heat transfer by increasing the surface area available for heat exchange. This results in a higher rate of heat transfer from the tube to the fluid.

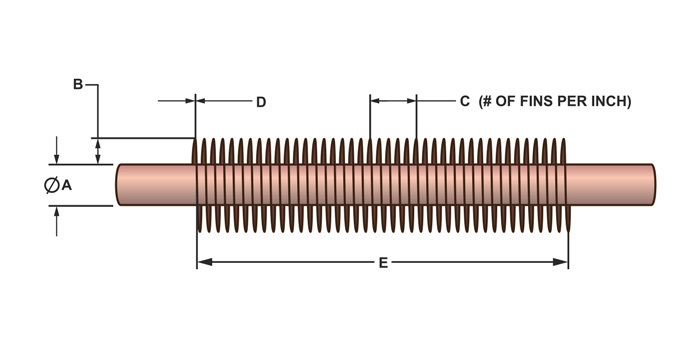

Factors Affecting Heat Transfer Rate

- Fin height and thickness:Taller and thicker fins provide a greater surface area for heat transfer.

- Fin material:Different materials have different thermal conductivities, which affects the rate of heat transfer.

- Fluid velocity:Higher fluid velocity increases the convective heat transfer coefficient, resulting in a higher heat transfer rate.

Comparison of Heat Transfer Rates

| Tube Type | Heat Transfer Rate (W/m2K) |

|---|---|

| Unfinned tube | 10-50 |

| Finned tube | 50-200 |

3. Design Considerations

The design of finned tube coils involves several key considerations:

Materials

- Tube material:Common materials include copper, steel, and aluminum.

- Fin material:Aluminum, copper, and stainless steel are commonly used.

Advantages and Disadvantages of Different Fin Materials, The fins on finned tube coils increase heat transfer by

| Material | Advantages | Disadvantages |

|---|---|---|

| Aluminum | High thermal conductivity, lightweight | Low strength, prone to corrosion |

| Copper | Excellent thermal conductivity, corrosion-resistant | Expensive, heavier than aluminum |

| Stainless steel | High strength, corrosion-resistant | Lower thermal conductivity than aluminum and copper |

4. Applications

Finned tube coils have a wide range of applications in various industries:

HVAC Systems

Finned tube coils are used in air conditioners, heat pumps, and other HVAC systems to transfer heat between the refrigerant and the air.

Refrigeration Systems

In refrigeration systems, finned tube coils are used in evaporators and condensers to transfer heat between the refrigerant and the environment.

Boilers

Finned tube coils are used in boilers to increase the heat transfer rate between the hot gases and the water.

Commonly Asked Questions

What are the benefits of using finned tube coils?

Finned tube coils offer increased heat transfer rates, reduced pressure drop, and improved thermal efficiency.

What are the different types of fins used in finned tube coils?

Common fin types include plain fins, serrated fins, louvered fins, and spiral fins.

In which industries are finned tube coils commonly used?

Finned tube coils find applications in industries such as power generation, refrigeration, air conditioning, and chemical processing.